What Does Premier Aluminum Llc Mean?

What Does Premier Aluminum Llc Mean?

Blog Article

Fascination About Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc Can Be Fun For AnyoneThe 9-Second Trick For Premier Aluminum Llc6 Easy Facts About Premier Aluminum Llc DescribedThe Basic Principles Of Premier Aluminum Llc

(https://www.quora.com/profile/Gary-Martin-1018)Using low expense and unqualified distributors can create high quality concerns, and threw away time and money in the long run. To help you through the procedure, here are some points to take into consideration when selecting the ideal steel casting vendor.

As an example, a business that just uses the investment casting procedure will certainly try to sell you on why that procedure is best for your application. Yet what if utilizing the sand casting procedure is best for you and your requirements? Rather, look for a distributor that offers an array of casting procedures so the finest option for YOU is chosen

If working with a solitary source for all of your spreading needs is essential to you, the provider needs to be varied in its abilities. When integrated with various other incorporated capacities, this can assist simplify and press the supply base. When choosing the right casting supplier, mindful factor to consider needs to be provided to high quality, solution, and rate.

An Unbiased View of Premier Aluminum Llc

Customers increasingly pick casting distributors who have machining abilities. If the casting vendor discovers an issue throughout machining, the trouble is resolved much faster with no dispute over whose fault it is.

Problem or no, incorporated machining simplifies the supply chain and lowers managing time and shipping price prior to the product makes it to the client. What do you require from your casting provider? Are you seeking somebody to just supply a metal component to your doorstep or do you require a lot more? As an example, if you do not have internal metallurgy proficiency, confirm that the distributor can offer advice in selecting the correct alloy based on your particular application - Aluminum Metal casting.

Some factories are limited or specialized. Make sure the supplier can satisfy all your material or alloy demands to remove the demand for numerous vendors.

Premier Aluminum Llc for Beginners

Study the provider's site. Talk to a sales rep or organization partner.

Light weight aluminum is also light-weight and has good rust resistance, making it excellent for applications where weight and durability are vital elements. In addition, light weight aluminum casting is an affordable method of manufacturing, as it requires less energy and sources than various other methods. Iron casting, on the other hand, involves putting molten iron right into a mold and mildew to create a preferred form.

Premier Aluminum Llc - Truths

Iron casting is also able to hold up against high temperature levels, making it ideal for usage in applications such as engine components and commercial equipment. However, iron spreading can be a lot more pricey these details than light weight aluminum spreading due to the greater expense of basic materials and the power called for to thaw the iron. When making a decision in between light weight aluminum casting and iron spreading, it is very important to take into consideration the details demands of the application.

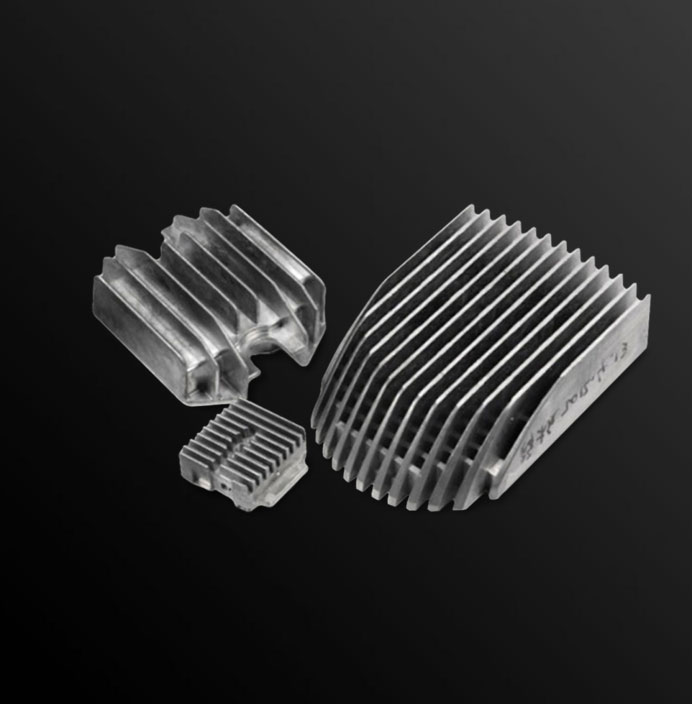

In verdict, both light weight aluminum casting and iron spreading have their own one-of-a-kind benefits and negative aspects. There are 3 sub-processes that drop under the classification of die spreading: gravity pass away casting (or irreversible mold and mildew casting), low-pressure die casting and high-pressure die casting. To get to the ended up product, there are three key alloys utilized as die spreading material to choose from: zinc, aluminum and magnesium. Report this page